Resistance to various applied forces is referred as mechanical properties. Some of these properties are briefly presented below:

1. Properties related to axial loading: For designing structural elements to resist the applied loads, the following strength properties should be known:

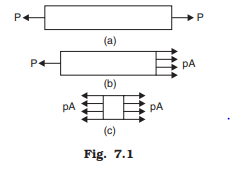

(a) Tensile strength: If an element is subjected to pulling forces, the resistance developed per unit area is termed as tensile stress and the maximum tensile stress the material can resist is termed as tensile strength. To find the resisting forces developed a section plane may be taken through the element and the equilibrium of any one part may be considered. Each part is in equilibrium under the action of applied forces and internal resisting forces. Fig. 7.1

shows a bar under tension and stresses at a cross-section and also an element of bar under tensile stress. In this P is the tensile force applied, p is the tensile stress (resistance per unit area) and A is the cross-sectional area.

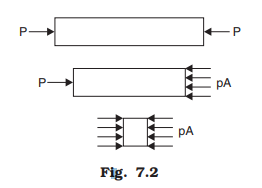

(b) Compressive stress: Instead of pull, if push ‘P’ acts on the element, it tries to shorten the bar and the internal resistance developed per unit area is called compressive stress

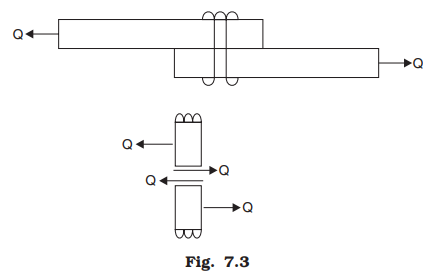

2. Properties related to shear loading:

If the applied force is trying to shear off a particular section of the element, the resistance developed for unit area in such case along that section is called shearing stress. The maximum stress that material can resist is called shearing strength of the material. Figure 7.3 shows a section of bolt under shearing stress

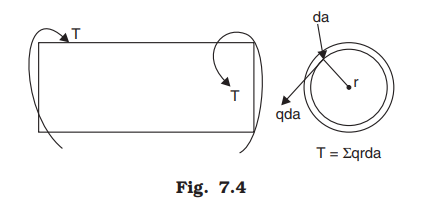

3. Properties related to torsional moment:

A member is said to be in torsion when it is subjected to a moment about its axis, Fig. 7.5 shows a shaft in torsion. The effect of a torsional member is to twist it and hence a torsional moment is also called as a twisting moment. In engineering problems many members are subjected to torsion. Shafts transmitting power from engine to rear axle of automobile, from a motor to machine tool and from a turbine to electric motor are the common examples of members in torsion. Ring beams of circular water tanks and beams of grid floors are also the examples of members in torsion. The applied torsion is resisted by the material of the member by developing shear stresses. This shear stress varies linearly from zero at centre of the shaft to the maximum value at the extreme fibre.

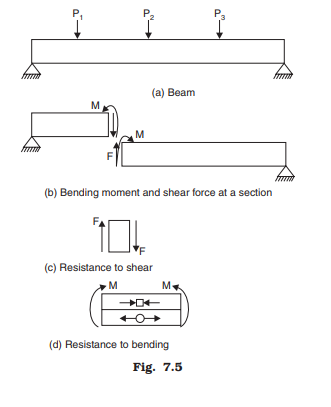

4. Properties related to bending:

When a member is supported at two or more points and subjected to transverse load it bends and develops resistance to the load. The cross-sections of the members are subjected to bending moment and shear force. Finally the load gets transferred to the support by end shear. The shear force introduces shear stresses in the material while bending moment introduces tension in some parts and compression in other parts as shown in Fig. 7.5.

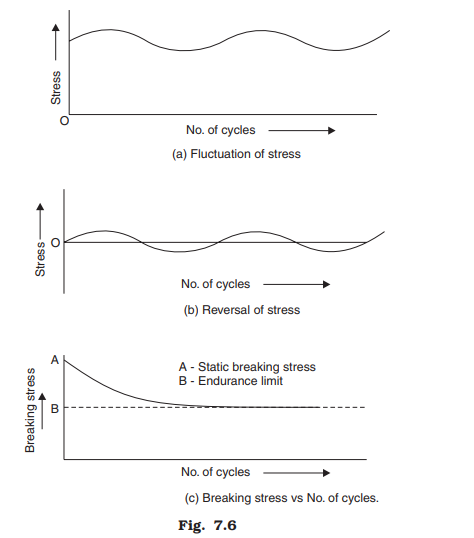

5. Fatigue:

Many structural members are subjected to fluctuation and reversal of stresses as shown in Fig. 7.6 (a) and (b). A bridge deck is a common example of fluctuation of stresses and the shaft is the mechanical component subjected to reversal of stresses. This type of stress when applied repeatedly reduces the strength of material and this effect is called fatigue. This property is shown in Fig. 7.6 (c). The maximum stress at which even a billion reversal of stresses cannot cause failure of the material is called endurance limit.

6. Abrasive resistance:

This is the property by virtue of which a material resists the forces acting at contact surfaces when one material rubs/moves over the other. This is an important property to be studied for the materials used for road surfaces and flooring.

7. Impact strength:

This property refers to the ability of the material to resist shock loads due to heavy loads falling on the surface.

8. Hardness:

It is the ability of the material to resist penetration from another material. A number called hardness number is used to measure hardness of various materials. It is based on hardnesses of ten minerals arranged in the increasing hardness. Diamond has hardness number 10. Sometimes hardness is measured by size of indentation of steel balls under standard pressure using hardness testing machine.

9. Elasticity:

It is the property of the material by virtue of which it regains its original shape and size after the removal of external load. The maximum stress level before which if the load is removed the material regains its shape and size fully is called its elastic limit.

10. Plasticity:

It is the property of the material to retain its changed shape and size after the loads are removed. It is a required property when a material is to be moulded into different shape.

11. Creep:

It is the property of the material by virtue of which it undergoes changes in size with time under the action of constant load. Concrete possesses this property.

12. Toughness:

It is the property of a material whereby it absorbs energy due to straining actions by undergoing plastic deformation.

The other terms proof stress, factor of safety, working stress and load factors are explained in the next chapter after explaining the stress strain curves. There are standard tests specified by codes to quantity various properties of the materials. Knowing the requirements of materials properties for different purposes, the engineer has to select or reject the materials to be used in construction.

Comments are closed