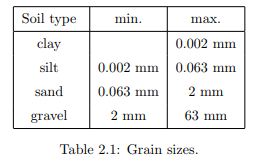

Grain size

Soils are usually distinguished into various types. In many cases these various types also have different mechanical properties. A simple subdivision of soils is on the basis of the grain size of the particles that constitute the soil. Coarse granular material is often denoted as gravel and finer material as sand. In order to have a uniformly applicable terminology it has been agreed internationally to consider particles larger than 2 mm, but smaller than 63 mm as gravel. Larger particles are denoted as stones. Sand is the material consisting of particles smaller than 2 mm, but larger than 0.063 mm. Particles smaller than 0.063 mm and larger than 0.002 mm are denoted as silt. Soil consisting of even smaller particles, smaller than 0.002 mm, is denoted as clay or luthum, see Table 2.1. In some countries, such as the Netherlands, soil may also contain

layers of peat, consisting of organic material such as decayed plants. Particles of peat usually are rather small, but it may also contain pieces of wood. It is then not so much the grain size that is characteristic, but rather the chemical composition, with large amounts of carbon. The amount of carbon in a soil can easily be determined by measuring how much is lost when burning the material.

The mechanical behaviour of the main types of soil, sand, clay and peat, is rather different. Clay usually is much less permeable for water than sand, but it usually is also much softer. Peat is usually is very light (some times hardly heavier than water), and strongly anisotropic because of the presence of fibres of organic material. Peat usually is also very compressible. Sand usually is rather permable, and rather stiff, especially under a certain preloading. It is also very characteristic of granular soils such as sand and gravel, that they can not transfer tensile stresses. The particles can only transfer compressive forces, no tensile forces. Only when the particles are very small and the soil contains some water, can a tensile stress be transmitted, by capillary forces in the contact points.

The grain size may be useful as a first distinguishing property of soils, but it is not very useful for the mechanical properties. The quantitative data that an engineer needs depend upon the mechanical properties such as stiffness and strength, and these must be determined from mechanical tests. Soils of the same grain size may have different mechanical properties. Sand consisting of round particles, for instance, can have a strength that is much smaller than sand consisting of particles with sharp points. Also, a soil sample consisting of a mixture of various grain sizes can have a very small permeability if the small particles just fit in the pores between the larger particles.

The global character of a classification according to grain size is well illustrated by the characterization sometimes used in Germany, saying that gravel partiecles are smaller than a chicken’s egg and larger than the head of a match, and that sand particles are smaller than a matchhead, but should be visible to the naked eye.

Grain size diagram

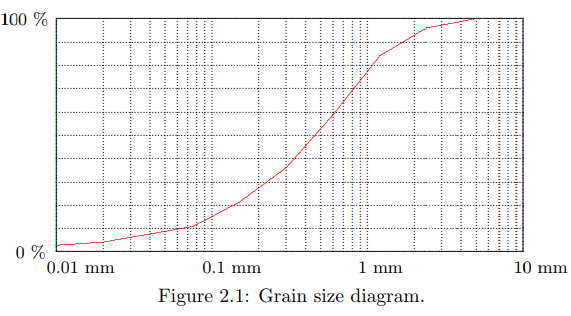

The size of the particles in a certain soil can be represented graphically in a grain size diagram, see Figure 2.1. Such a diagram indicates the percentage of the amount of particles smaller than a certain diameter, measured as a percentage of the weight. A steep slope of the curve in the diagram indicates a uniform soil, a shallow slope of the diagram indicates that the soil contains particles of strongly different grain sizes. For rather coarse particles, say larger than 0.05 mm, the grain size distribution can be determined by sieving. The usual procedure is to use a system of sieves having different mesh sizes, stacked on top of each other, with the coarsest mesh on top and the finest mesh at the bottom. After shaking the assembly of sieves, by hand or by a shaking machine, each sieve will contain the paricles larger than its mesh size, and smaller than the mesh size of all the sieves above it. In this way the grain size diagram can be determined. Special standardized sets of sieves are available, as well as convenient shaking machines. The example of Figure 2.1 shows a normal sand. In this case there are no grains larger than 5 mm.

The grain size distribution can be characterized by the quantities D60 and D10. These indicate that 60 %, respectively 10 % of the particles (expressed as weights) is smaller than that diameter. In the case illustrated in Figure 2.1 it appears that D60 ≈ 0.6 mm, and D10 ≈ 0.07 mm. The ratio of these two numbers is denoted as the uniformity coefficient Cu,

In the case of Figure 2.1 this is about 8.5. This indicates that the soil is not uniform. This is sometimes denoted as a well graded soil. In a poorly graded soil the particles all have about the same size. The uniformity coefficient is than only slightly larger than 1, say Cu = 2.

For particles smaller than about 0.05 mm the grain size cannot be determined by sieving, because the size of the holes in the mesh would become unrealistically small, and also because during shaking the small particles might fly up in the air, as dust. The amount of particles of a particular size can then be determined much better by measuring the velocity of deposition in a glass of water. This method is based upon a formula derived by Stokes. This formula expresses that the force on a small sphere, sinking in a viscous fluid, depends upon the viscosity of the fluid, the size of the sphere and the velocity. Because the force acting upon the particle is determined by the weight of the particle under water, the velocity of sinking of a particle in a fluid can be derived. The formula is

where γp is the volumetric weight of the paricle, γf is the volumetric weight of the fluid, D is the grain size, and µ is the dynamic viscosity of the fluid. Because for very small particles the velocity may be very small, the test may take rather long.