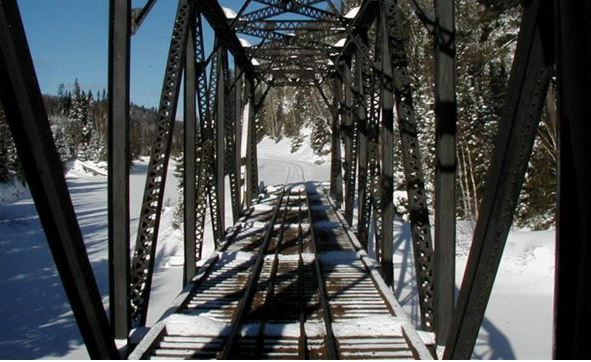

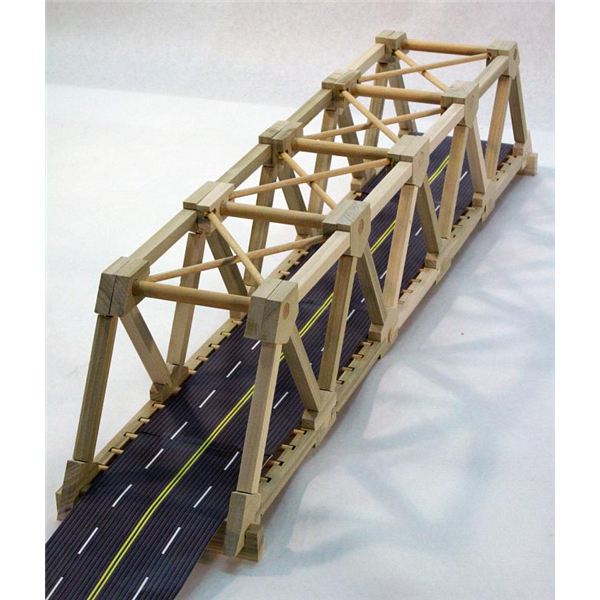

Truss bridges are amongst a variety of bridge designs that are being used for road traffic. The basic shape of a truss bridge is like a right triangle, with the hypotenuse extending to the abutments. There are two similar trusses at each of the road sides.

Basics of Truss Bridges

Truss is a formation produced by triangular components, in accordance with the truss bridge drawings, and coupled at joints known as nodes. The triangular units forming the truss are slim and straight in form. The truss bridges consist of a grouping of triangles that are manufactured from straight and steel bars, according to the truss bridge designs. The solid arms of the triangle are extended from the pier sides. The diagonal steel tubes project from the bottom and top of each pier, and assist in holding the arms in the correct position. Trusses are organized as straight elements that are connected at the ends by hinges to develop a secure arrangement.

On application of loads on the truss joints, forces are communicated to the truss elements. The steel truss bridge members are in compression or tension. The trusses possess a high ratio of strength to weight, and therefore are useful for being employed in truss bridges. Trusses are also suitable for use in several other structures like roof supports and space stations. Amongst the modern bridges, truss bridges are considered to be included in the older kinds. The famous truss bridges are relatively inexpensive due to effective utilization of the bridge materials. The truss bridge designs are an important factor in architecture.

Truss Bridge Construction

Truss bridge construction is initiated with a detailed soil analysis to determine suitability for the bridge and traffic loads. The truss bridge is designed with either the road being at the truss bottom, or alternatively with the road being at the truss top. The former design has the bridge elements under compression, while the elements of the later design are mostly under tension. The bridge materials are selected and either welded or bolted, according to the requirement. The concrete is poured in the abutments, with the anchor bolts firmly inserted. Finally, the trusses are built, and the bridge is ready for use.

Truss Bridge Designs

A truss bridge is designed using Newton’s laws of motion and incorporating pin joints. Pin joints are places at which straight elements of the truss formation meet. It is assumed that only the tensile and compressive forces operate on the truss elements. The truss bridge comprises vertical, horizontal, and the diagonal elements. The vertical members are under tension, while the horizontal elements are subjected to bending, shear, and tensile loads. The diagonal elements are under compressive forces.

Kinds of Truss Bridges

There are numerous forms of truss bridges that depend upon the topography and the purpose to be obtained by the bridge. The common types of truss bridges are as explained below:

Howe Truss

The Howe truss consists of diagonal and vertical elements. The diagonal elements slope towards the bridge center in an upward direction. The vertical elements are under tension. This is a rare type of truss bridge originally patented in 1840 by William Howe. Famous examples are the Jay Bridge in New York and the Sandy Creek Covered Bridge in Missouri

Lenticular Truss

This kind of bridge uses a lens-shape truss. An upper arch curves up and then down, and a lower one curves down and then up. The two arches meet at the same end points. Examples of this bridge include the Royal Albert Bridge in UK and the Smithfield Street Bridge in Pennsylvania.

Bailey Bridge

This bridge is normally utilized to cover obstacles by the military tanks and other equipment. It can be constructed without the need of heavy tools or machinery.

K Truss

The bridge design is complex, and the construction requires extensive use of heavy equipment. The bridge elements under tension are reduced in number.

Bowstring Arch Truss

This bridge was patented in 1840 by S. Whipple. The main characteristic here is that the vertical loads on the thrust arches are transmitted along the arc path. At the end of the arch, the thrust is resolved into vertical and horizontal components.

Pegram Truss

In this bridge, the upper chords are all of equal length and the lower chords are longer than the corresponding upper chord. Because of this difference, each panel is not square.This truss design was patented by George H. Pegram in 1885. Only ten Pegram bridges remain in the United States, and seven of them are in Idaho.