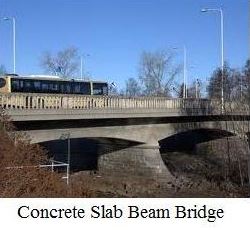

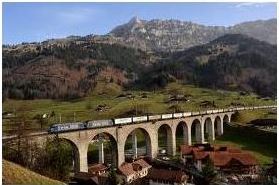

Beam bridges, also known as girder bridges, are one of the oldest and most common types of human construction. They are supported by land structures like river banks or by piers at both ends. Box girders or trusses may be used to strengthen the beam. Highway overpasses are normally beam bridges.

The History of Beam Bridges

Bridges have been constructed by human beings since the ancient times, with the initial design being extremely simple consisting of a tree placed across a stream or a river. With the advancement of civilization, more useful methods were discovered in bridge building that were based on the utilization of rock, stone, mortar, and other construction materials to build bridges that were stronger and longer. Roman techniques for bridge building included the driving of wooden poles, at the intended location of the bridge columns, and then filling the column space with the construction materials. The bridges built by the Romans were strong and of a uniform strength. After the industrial revolution, materials science developed rapidly with the introduction of materials with enhanced physical properties, and wrought iron was replaced with steel since it had a greater tensile strength. Presently, four main kinds of bridges are used, namely beam, arch, cantilever, and suspension.

The Construction of Beam Bridges

The beam bridge, also known as a girder bridge, is a firm structure that is the simplest of all the bridge shapes. Both strong and economical, it is a solid structure comprised of a horizontal beam, being supported at each end by piers that endure the weight of the bridge and the vehicular traffic. Compressive and tensile forces act on a beam bridge, due to which a strong beam is essential to resist bending and twisting because of the heavy loads on the bridge. When traffic moves on a beam bridge, the load applied on the beam is transferred to the piers. The top portion of the bridge, being under compression, is shortened, while the bottom portion, being under tension, is consequently stretched and lengthened. Trusses made of steel are used to support a beam, enabling dissipation of the compressive and tensile forces. In spite of the reinforcement by trusses, length is a limitation of a beam bridge due to the heavy bridge and truss weight. The span of a beam bridge is controlled by the beam size since the additional material used in tall beams can assist in the dissipation of tension and compression.

The Future of Beam Bridges

Extensive research is being conducted by several private enterprises and the state agencies to improve the construction techniques and materials used for beam bridges. The beam bridge design is oriented towards the achievement of light, strong, and long-lasting materials like reformulated concrete with high performance characteristics, fiber reinforced composite materials, electro-chemical corrosion protection systems, and more precise study of materials. Modern beam bridges use pre-stressed concrete beams that combine the high tensile strength of steel and the superior compression properties of concrete, thus creating a strong and durable beam bridge. Box girders are being used that are better designed to undertake twisting forces, and can make the spans longer, which is otherwise a limitation of beam bridges. The modern technique of the finite element analysis is used to obtain a better beam bridge design, with a meticulous analysis of the stress distribution, and the twisting and bending forces that may cause failure.