The Seikan Tunnel is one of the best examples of engineering. Its construction process provided useful technologies that have been used worldwide.

Introduction

The idea of building the Seikan Tunnel was introduced before the Second World War, but the actual investigation about building the tunnel was started after the war. The requirement of Seikan Tunnel was propelled after the Toya Maru ferry accident in 1954. Construction was finally started in 1964 with the first investigational inclined shaft sunk on the Hokkaido.

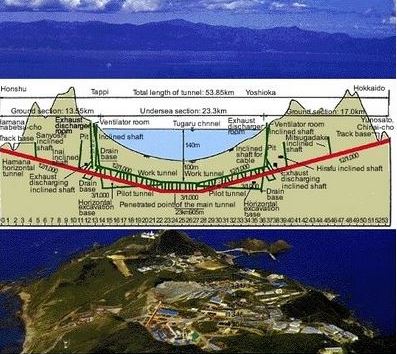

Afterward, overcoming many difficult problems, the primary shaft of the tunnel was opened on March in 1985. The first trial run was performed on Oct. 21st 1987. The Seikan Tunnel, Yoshioka, and Tappi Undersea Stations started service on March 13th, 1988. This undersea tunnel links the main island of Honshu with the northern island of Hokkaido and offers a safer way for crossing the Tsugaru Strait.

Shafts of the Seikan Tunnel

• Vertical shaft

These shafts are constructed vertically downwards. These shafts were used for elevators to haul workers, materials, and machinery. Now these shafts are used for circulating fresh air inside the tunnel.

• Main shaft

This is the main tunnel, in which the railway lines are placed. This shaft is constructed 7.85 meters high and 9.7 meters wide.

• Pilot drift shaft

It was used as a supporting shaft for digging the main shaft and the construction shaft. Testing and research of the nature of the soil and sea water leakage were performed using this shaft. The digging operations were performed after all these inspections. Presently, this shaft is used for drainage and ventilation.

• Construction shaft

The construction shaft is built to the side of the main shaft. This shaft was used for connecting guide paths. It was very important because it enhanced the pace of digging by increasing the face. It was also used for transporting materials and machineries.

• Inclined shaft

Two main inclined shafts were constructed, first in Yoshioka and the second in Tappi. It was made inclined at an angle of 14 degrees to the side of seabed, and it was mainly used for geological surveys. Rather, it was also used for transporting workers, materials, machinery, and the rocks and mud left due to the dig. Now, a cable car is used in this shaft to carry materials.

Facts about the Seikan Tunnel

• The entire tunnel is 53.85 km long, of which the seabed section is 23.30 km and surface section is 30.55 km.

• The maximum curve radius of the tunnel is 6.500 m.

• The maximum grade of the tunnel is 12/1000.

• The minimum overburden under seabed is 100 m.

• The maximum depth of the sea is 140 m.

• The cross section of the tunnel is a double track Shinkansen type.

• Approximately 85,000 tons of cement was used to construct the tunnel.

• The amount of steel materials used in the tunnel was17,000 tons.

• The amount of soil dug was approximately 630 thousand square meters.

• Approximately 2,900 tons explosives were used.

• 14 million workers were employed during the peak of construction.

• The Yoshioka Undersea Station and Tappi Undersea Station are positioned 149.5m and 135.0 m below the sea level, respectively.

• The overall construction cost of the Seikan Tunnel was 690 billion yen.

• Bicycles and diesel engine trucks are used for the inspection of the tunnel.

• Two gasoline-powered passenger cars are used for inspection of the main shaft.

• A cable car is used for going inside the tunnel from the ground. This car can move at 150 m per minute.

• The environment of the tunnel is maintained with the temperature 20 degree Celsius, and humidity is maintained in between 80 to 90 percent.

• Maintenance bases are constructed inside the tunnel, in which the largest base is 16 m wide, 10 m high, and 91 m long.

Summary

The Seikan Tunnel is one of the largest tunnels in the world. Most of the technologies used in its construction were applied for the first time, and now, these technologies are used worldwide. The process of inspection of this tunnel is unique, and the Seikan Tunnel is a lasting gift of engineering for Japan.