Overtaking the wood truss as a popular choice for structural design, the steel truss has become an important architectural and structural engineering element. Cold forming into curvilinear engineered steel trusses creates an astounding variety of architectural design.

History And Types Of Steel Trusses

As a relatively new building material, steel has become especially useful when incorporated into engineered steel trusses and steel plate connected timber trusses. Attempts were made in the 17th and 18th centuries to use iron as reinforcing and structural members, especially in bridge design for railroads and other heavy load applications. However, it became tragically apparent that structural iron quality control and design methods did not have the necessary reliability and cost factors required for widespread use. With the development of the Bessemer process in 1858 the cost of manufacturing steel began to drop, and with the Linz-Donawitz process 100 years later steel began to seriously compete with wood as a structural framing element. Electric arc furnaces enabled efficient steel recycling processes, further decreasing production costs. Finally, the cold rolled process for producing steel truss members now enables low cost production of steel floor trusses, steel roof trusses, entire steel truss buildings, and the elements used in the design of steel truss bridges. All have now become cost effective, reliable, and safe alternatives to more traditional structural framing materials.

Design And Use Of Engineered Steel Trusses

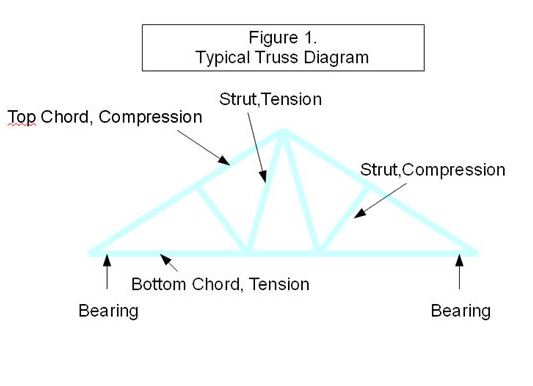

Based on engineered wood truss designs, steel trusses also follow the common triangular chord and strut configuration as demonstrated in Figure 1:

The top chords typically bear loads directly, and the resulting tension and compression load distribution through the struts to the bottom chord accounts for the greater overall load bearing capabilitys of the wood truss.

A commonly observed use of the triangular steel truss system is for electric grid power line distribution towers, for example.

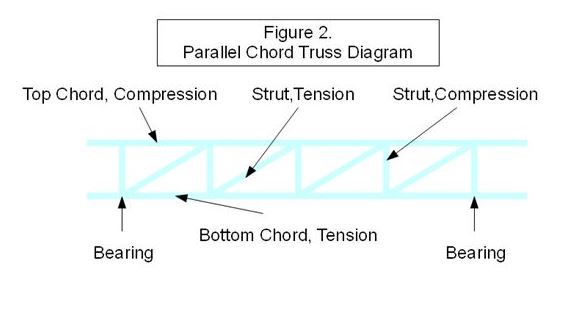

In fact, any wood truss design can now be competitively manufactured using steel elements. The engineering benefits of doing so are lighter weight and better resistance to rot, insect damage, and splitting. A significant architectural advantage of steel over wood is the ability to cold form arches and curves as chord members, further increasing the design versatility as well as engineering stiffness. By incorporating parallel chords much larger spans can be achieved for lightweight coverings and vertical constructions. A parallel chord truss typically uses tubular steel elements and two or more parallel chords much longer that the webs, or struts, as shown in Figure 2:

Note that the parallel chords need not be straight but can be curvilinear, lending additional architectural variety to these structural elements. Knowing the expected live and dead loads, the bearing points, overhangs, and other structural factors, spans over 300’ can be engineered with these steel trusses.

Arches are particularly useful with this application, creating large enclosed or semi-enclosed structures such as aggregate storage facilities, barns, manufacturing enclosures, workshops, etc.