Portland Pozzolana Cement

1. POZZOLANA

Pozzolana is a volcanic powder found in Italy near Vesuvius

A pozzolanic material is essentially a siliceous or aluminous material which possess no cementitious properties. But it has the property when it combined with lime to produce a stable pozzolana compound it has definite cementitious properties.

In the presence of water Pozzolana reacts with calcium hydroxide, liberated in the hydrogen process at ordinary temperature to produce compounds possessing cementitious process.

By adding the additional pozzolana such as fly ash calcium hydroxide coverts into calcium silica hydrated gel

Ca (OH)2 + pozzolana + Water -> C-S-H (gel)

C-S-H gel is responsible for most of the engineering properties of cement paste and it occupies the half of the volume of paste phase. It is microscopic structure

When C-S-H gel will be dried in that place pores will be formed and leads to reduction in strength .it can be minimized by maintain proper hydration.

Artificial pozzolanas: Fly ash, silica fume, rice husk, blast furnace slag.

Natural pozzolanas: Burnt clay, pumicite, diatomaceous Earth.

By replacing the pozzolana in cement content ball bearing effect and particle packing effect can be reduced in the concrete.

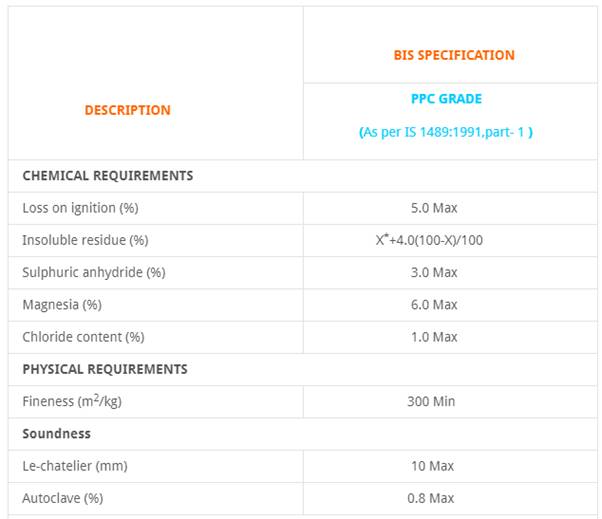

Pozzolanic materials generally used for manufacture of Portland cement are calcinated clay (lS: 1489 part 2 of 1991) or fly ash (IS: 1489 part 1 of 1991)

Composition and manufacturing of pozzolana Portland cement (PPC):

§ Pozzolana Portland cement is manufactured by grinding Portland cement clinker and pozzolana (usually fly ash 10 to 30 % by mass of PPC) or by intimately and uniformly Portland cement and fine pozzolana. As per the latest amendment the proportion of pozzolana may vary from 15 to 35 % by weight of clinker earlier it was 10 to 15 %

§ By adding the fly ash content up to the permissible limits increases the long term strength ,durability and reduce the volume changes

§ Carbon dioxide emission can be reduced by adding fly ash in cement concrete

§ Maintain Low tri-calcium aluminate content in PPC which ig good against sulphate attack

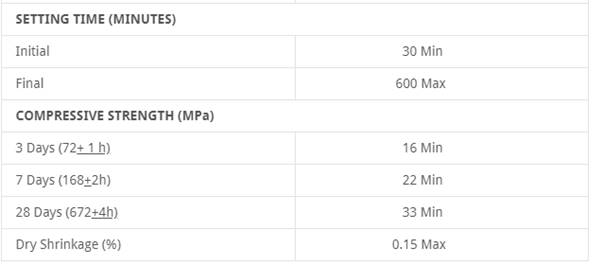

§ Average compressive strength of mortar cube (area of face 50 cm2) composed of 1:3 by mass and (p/4) +3% of (combined mass of cement and sand)

1. At 7 days 22 MPa (minimum)

2. At 28 days 33 MPa (minimum)

{Where P is % of water to produce a paste of standard consistency}.

§ Initial setting time = 30 min (minimum)

§ Final setting time = 600 min (maximum).

§ Drying shrinkage should not be more than 0.15%

§ fineness should not be less than 300 m2/kg

§ Initial strength of PPC is less but final strength is equal to the 28 days strength of OPC

§ PPC has lower rate of development of strength than OPC

1.1 ADVANTAGES OF PPC:

§ It increases the workability

§ It can reduce permeability

§ Reduces water evaporation

§ Honey combing will be reduced

§ Improves cohesion that means less segregation

§ Increases the elastic modulus of concrete

§ Less heat of hydration

§ Gives good surface finishing

§ Slump can be minimized

§ PPC used in pre-stressed and post-tensioned concrete

§ Offers greater resistance to aggressive weather

§ It can reduce shrinkage ,creep and bleeding

§ By using PPC global warming can be minimized

§ Leaching in concrete reduces

§ Used in high rise buildings which serves life more than 100 years

§ Used in mass concreting

§ PPC reduces sulphate attack

§ It is particularly used in marine and hydraulic structure

§ By using PPC cost of construction should be reduced

§ Used in Concrete pavements

§ Used in pre casted pipes and blocks

§ Used in harsh environments such as tunnel linings

§ In hardened concrete it can reduce carbonation

1.2 DISADVANTAGES OF PPC:

§ Reduction in alkanity reduces the resistance to corrosion of steel reinforcement

§ Curing period is less for PPC due to that may have chances for un hydrated cement concrete

§ Due to the more fineness proper handling should be done

§ Earliest strength gain is less

§ When compared to the OPC setting time is less for PPC

Comments are closed