Concrete can be imported by variety of methods and equipment’s methods adopted for transportation of concrete

· Mortar pan

· Wheel barrow

· Crane, bucket and rope way

· Truck mixers and dumpers

· Belt conveyors

· Chute

· Skip and hoist

· Transit mixer

· Pump and pipe line

· Helicopter

Mortar pan

This case concrete is carried out in small quantities. This method exposes greater surface area of concrete for drying conditions. This results a geat loss of water particularly in hot weather. Mortar pan must be wetted to start with and must be kept clean.

Wheel barrow

Used for transporting concrete in ground level. This method is employed for hauling concrete in longer distance in case of concrete road construction. If the distance is long or ground is rough it is likely that the concrete get segregated due to vibration. To avoid this, wheel barrows are provided with pneumatic wheel.

Crane bucket and rope way

This is one of the right way for transporting concrete above the ground level. Crane can handle concrete in high rise construction project and are becoming familiar sites in big cities. Rope way buckets of various sizes are used.

Rope way method is adopted for

· Concrete works in valley

· Construction work of the pier in the river

· For dam construction

Truck mixer and dumpers

For large concrete works particularly for concrete to be placed at ground level. These are ordinary open steel tipping lorries Dumpers having 2-3 cubic meter capacity Belt conveyors also can be used.

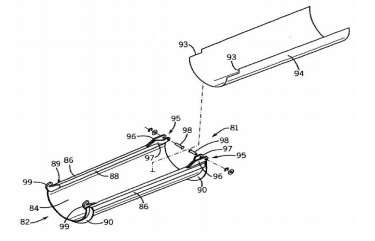

Chutes

Provided for transporting concrete from ground to lower level. The surface should have same slope not flatter than 1 vertical to 2 and a1/2 horizontal

Skip and hoist

Adopted method for transporting concrete vertically for 3 to 4 floors. Mortar pan with staging and human ladder is used for transporting concrete.

Transit mixer

This is the equipment for transporting concrete over a big distance particularky ready mix concrete. They are truck mounted having a capacity of 4 to 7 m3. The speed of rotation of truck mixer is 4to16 rev/min. A small concrete pump is also mounted on the truck carrying transit mixer.

Pumps and pipe lines

Universally accepted method Starts with the suction stroke for suck the concrete inside the pipe. It has a piston which moves forward and backward to have suction and delivery of concrete

· Choosing a correct pump involves

· Length of horizontal pipe

· Length of vertical pipe

· Number of bends

· Diameter of pipe line

· Length of flexible hose

· Change in line diameter

· Slump of concrete