To eliminate or minimize the systematic errors of taping, it is necessary to adjust each measured bay to its final horizontal equivalent as follows.

Standardization

During a period of use, a tape will gradually alter in length for a variety of reasons. The amount of change can be found by having the tape standardized at either the National Physical Laboratory (NPL) for invar tapes or the Department of Trade and Industry (DTI) for steel tapes, or by comparing it with a reference tape kept purely for this purpose. The tape may then be specified as being 30.003 m at 20◦C and 70 N tension, or as 30 m exactly at a temperature other than standard.

Worked examples

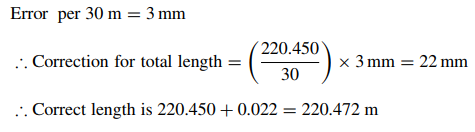

Example 4.1. A distance of 220.450 m was measured with a steel band of nominal length 30 m. On standardization the tape was found to be 30.003 m. Calculate the correct measured distance, assuming the error is evenly distributed throughout the tape.

Note that:

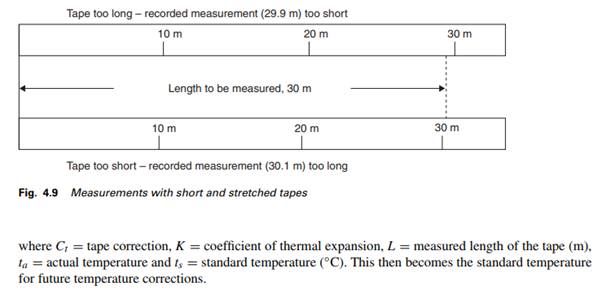

(1) Figure 4.9 shows that when the tape is too long, the distance measured appears too short, and the correction is therefore positive. The reverse is the case when the tape is too short.

(2) When setting out a distance with a tape the rules in (1) are reversed. (3) It is better to compute Example 4.1 on the basis of the correction (as shown), rather than the total corrected length. In this way fewer significant figures are required.

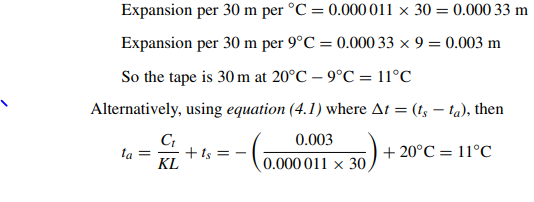

Example 4.2. A 30-m band standardized at 20◦C was found to be 30.003 m. At what temperature is the tape exactly 30 m? Coefficient of expansion of steel = 0.000 011/◦C