Trusses are the frame formed by number of straight members connected in the form of triangles

The embers are made by steel angles and they are joined by rivet or welding, these joints are called nodes

It is assumed that the external loads act at the nodes only and the members are subjected to only tension or compression

The compression members are called as struts and the tension members are called as ties

Steel roof trusses are used under the following condition

Large spans are to be covered

Intermediate columns are to be avoided to have an unobstructed working area inside

There is a heavy rain or snow fall

Types of roof trusses

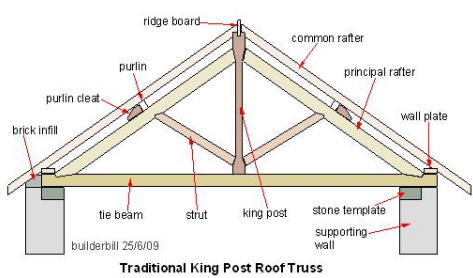

King post truss

Here the common rafters are supported by wooden frame work called truss under required interval

The frame work consist of a king post, two struts two principal rafters and tie beam

The truss rest on stone bed blocks at either end

The common rafters rest on wooden purlins which in turn are fixed to the principal rafters of the truss

The king post connect the ridge post and the middle of the tie beam

The struts are connected to the king post at the bottom and the principal rafters at the top

The roofing material is fixed to the common rafters king post truss is used for spans of 5m to 9m

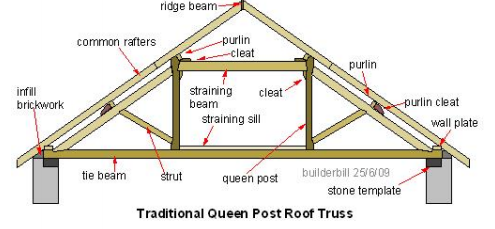

Queen post truss

The frame work consist of two principal rafters ,two queen post one straining sill two struts one tie beam and one straining beam.

The common matters rest on wooden purlins

The staining beam resist the horizontal thrust developed

The struts are connected to the queen post at the bottom and the principal rafters at the top

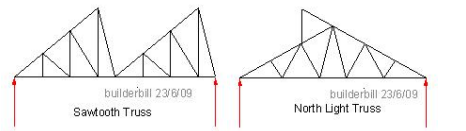

North light roof truss

North light or saw tooth roof truss is special type of roof trusses suitable for factories engaging in manufacturing work

North light truss is sawtooth

Actual lighting is taken an advantage during day time by using the north light roof trusses In this type of trusses vertical drops are provided this drops are covered with glasses so as to permit light in to the interior

Centering and shuttering

Shuttering is the temporary ancillary construction used as a mould for the structures In which the concrete is placed and allowed to hardened

These are classified as steel wooden plywood combined woods steel, reinforced concrete and plain concrete

Requirements of shuttering The material should be cheap and should be suitable for re use several times

It should be practically water proof so that it should not observe water from concrete

It should be strong enough to with stand all loads coming on it

It should be stiff enough so that deflection is minimum

The surface of the formwork should smooth and it should afford easy stripping

Loads on form work

Live load due to labour etc

Dead weight of wet concrete

Hydrostatic pressure of the fluid concrete

Impact due t pouring concrete

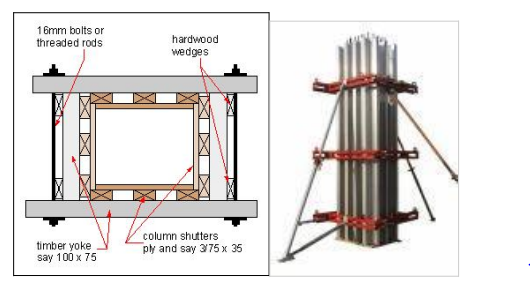

Shuttering for column

Components

Sheeting or column shutter all around the column

Yokes

Wedges

Bolt

Shuttering for beam and slab floor

The slab is continous over the beam

The slab is supported on 2.5 cm thick sheeting laid parallel to the main beam

The boarding may be 4 to 5 cm thick for walls up to 3to 4m high

The boards are fixed to 5cmX10cm posts known as struts are soldiers.