Introduction Design of foundations presupposes that the soil conditions (profile and parameters) at the site have been established by a geotechnical site investigation. Site investigations employ soil sampling and in-situ sounding methods. Most methods consist of intermittent sampling, e.g., the standard penetration test with split-spoon sampling and probing for density—the N-index. Other intermittent methods are the vane, dilatometer, and pressure meter tests. The only continuous in-situ test is the cone penetrometer test.

In-situ sounding by standardized penetrometers came along early in the development of geotechnical engineering. For example, the Swedish weight-sounding device (Swedish State Railways Geotechnical Commission 1922), which still is in use in Sweden and Finland. The cone stress obtained by this device and other early penetrometers included the influence of soil friction along the rod surface. In the 1930s, a “mechanical cone penetrometer” was developed in the Netherlands where the rods to the cone point were placed inside an outer pipe (a sleeve), separating the cone rods from the soil (Begemann 1963). The mechanical penetrometer was advanced by first pushing the entire system to obtain the combined resistance. Intermittently, every even metre or so, the cone point was advanced a small distance while the outer tubing was held immobile, thus obtaining the cone stress separately. The difference was the total shaft resistance.

Begemann (1953) introduced a short section sleeve, immediately above the cone point. The sleeve arrangement enabled measuring the shaft resistance over a short distance (“sleeve friction”) near the cone. Sensors were placed in the cone and the sleeve to measure the cone stress and sleeve friction directly and separately (Begemann 1963). This penetrometer became known as the “electrical cone penetrometer”.

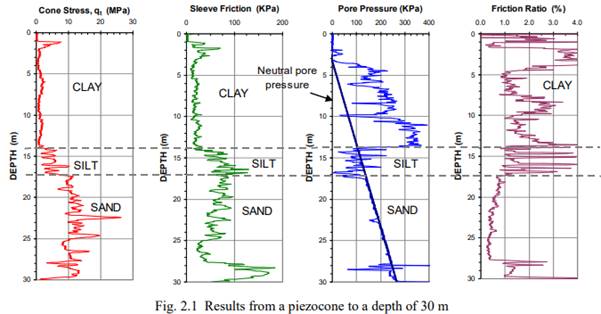

In the early 1980s, piezometer elements were incorporated with the electrical cone penetrometer, leading to the modern cone version, “the piezocone”, which provides values of cone stress, sleeve friction, and pore pressure at close distances, usually every 25 mm, but frequently every 10 mm—indeed, there is no reason for not recording at every 10 mm. (The shear resistance along the sleeve, the “sleeve friction” is regarded as a measure of the undrained shear strength—of a sort—the value is recognized as not being accurate; e.g., Lunne et al. 1986, Robertson 1990). Fig. 2.1 shows an example of a piezocone to a depth of 30 m at the site where the soil profile consists of three layers: an upper layer of soft to firm clay, a middle layer of compact silt, and a lower layer of dense sand. The groundwater table lies at a depth of 2.5 m. The CPT values shown in the diagram have been determined at every 50 mm. (Note, nothing is gained by widening distance between measuring points. Instead, valuable information may be lost.).

While a CPT sounding is always aimed vertical, it might bend and drift in the soil, which will cause the cone point to deviate from the vertical below the starting point. This also means that the sounding depth will be shorter; the cone point “lifts”. For most cone soundings, deviation from the depth and exact location vertically below the “cone location” is inconsequential. However, for deep soundings, both deviations can be substantial. Modern CPT equipment will always measure the deviation from the vertical in two directions, which allows the operator and user to calculate the deviation from the ideal. Curiously, the inclination measurements are often not included with a final report. They should be.

The cone penetrometer does not provide a measurement of static resistance, but records the resistance at a certain penetration rate (now standardized to 20 mm/s). Therefore, pore water pressures develop in the soil at the location of the cone point and sleeve that add to the “neutral” pore water pressure. In dense fine sands, which are prone to dilation, the induced pore pressures can significantly reduce the neutral pressure. In pervious soils, such as sands, the pore pressure changes are small, while in less pervious soils, such as silts and clays, they can be quite large. Measurements with the piezocone showed that the cone stress must be corrected for the pore pressure acting on the cone shoulder (Baligh et al. 1981; Campanella et al. 1982, Campanella and Robertson 1988). See Section 2.2.6 and Eq. 2.1 below

The cone penetrometer test is simple, fast to perform, economical, supplies continuous records with depth, and allows a variety of sensors to be incorporated with the penetrometer. The direct numerical values produced by the test have been used as input to geotechnical formulae, usually of empirical nature, to determine capacity and settlement, and for soil profiling.

Early cone penetrometers gave limited information that could be used for determining soil type and were limited to determining the location of soil type boundaries. The soil type had to be confirmed from the results of conventional borings. Empirical interpretations were possible but they were limited to the geological area where they had been developed. Begemann (1965) is credited with having presented the first rational soil profiling method based on CPT soundings. With the advent of the piezocone, the CPTU, the cone penetrometer was established as an accurate site investigation tool.

This chapter is a summary to indicate some of the uses of the cone penetrometer test. For a more thorough account, the reader is directed to the many reports and papers by Tom Lunne, Paul Mayne, and Peter Robertson, specifically, Kulhawy and Mayne (1990), Lunne et al. (1986), Lunne et al. (1997), Mayne et al. (1990), Mayne et al. (2001), Mayne et al. (2002)., Mayne (2007), Robertson and Campanella (1983), and Robertson 2007.

An account of the use of results from CPTU soundings to analyze the response of a pile to applied load belongs here, but it is instead treated in Chapter 7, Static Analysis of Pile Load Transfer to present it in the context of how it is applied.